Axlering types

One-piece axle-ring with pressed-in cable guides

The one-piece axle-ring was mounted on all internal gear mech versions until the beginning of 2003 (until Serial Number 25300). This type of Axle-ring is secured to the gearbox with six axleplate screws. The cable guides of the one-piece axle-ring remain fixed to the axle-ring. This can be seen once the axleplate has been removed. To replace the hub cable, the axle-ring complete with the cable pulley must be removed (use spare part = ‘Hub cables’ Art. #8271).

Quick-change axle-ring with cable guides seated within nylon cylinders

The quick-change axle-ring is secured to the gear box with five axleplate screws. The axle-ring remains secured to the gearbox with one more screw and the cable guides seated within black nylon cylinders rest in the axle-ring. This can be seen once the axleplate has been removed. When replacing the hub cable, the axle-ring remains attached to the SPEEDHUB.

Replacement procedure see Quick-change axle-ring

Mounting Guide Video

Quick-change Axle-ring

A Hub Cable Easy Set (Art. #8573) is available for a quick replacement. A Hub Cable including all needed parts can simply be slotted into the axle-ring as a complete unit (see included instruction sheet for mounting instructions). To spare parts in the shop.

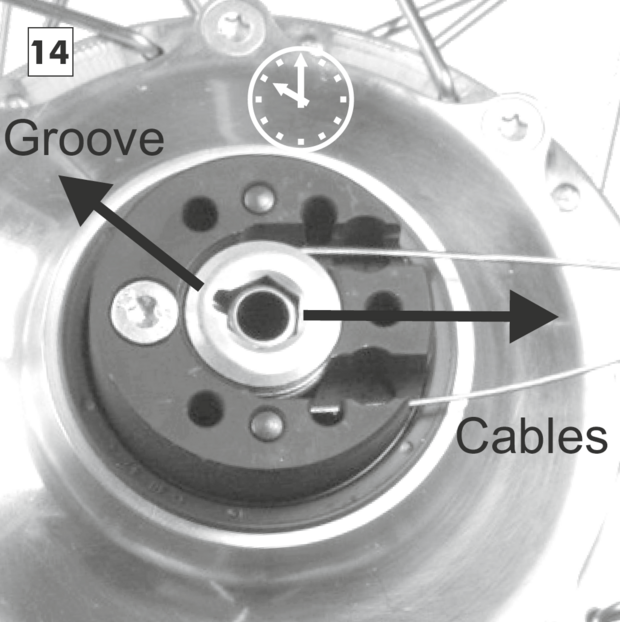

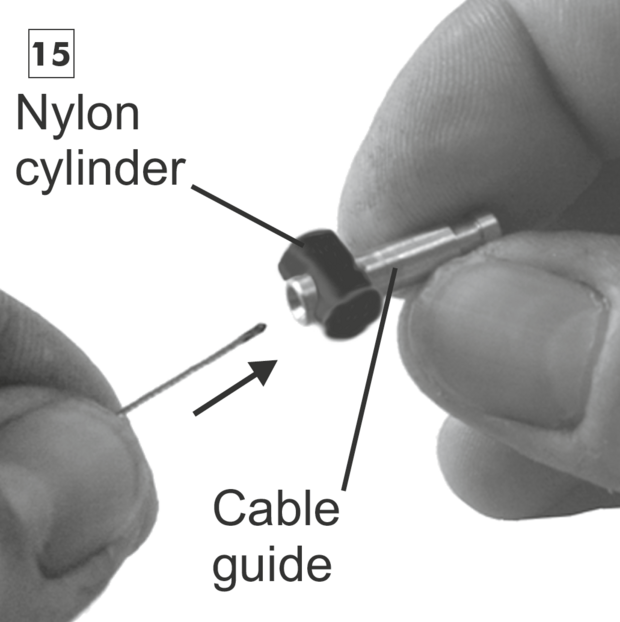

The axle-ring remains attached to the axle by one more countersunk head bolt underneath the axleplate. Lie the wheel on a worktop with the axle-ring facing upwards. Remove the two cable guides with the nylon cylinders and the cable pulley by rocking the cable guides from side to side until they are released from their seats within the axle-ring.

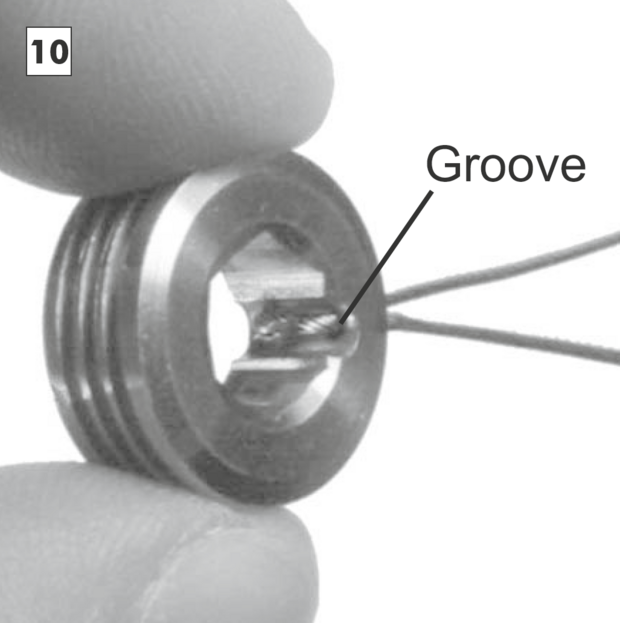

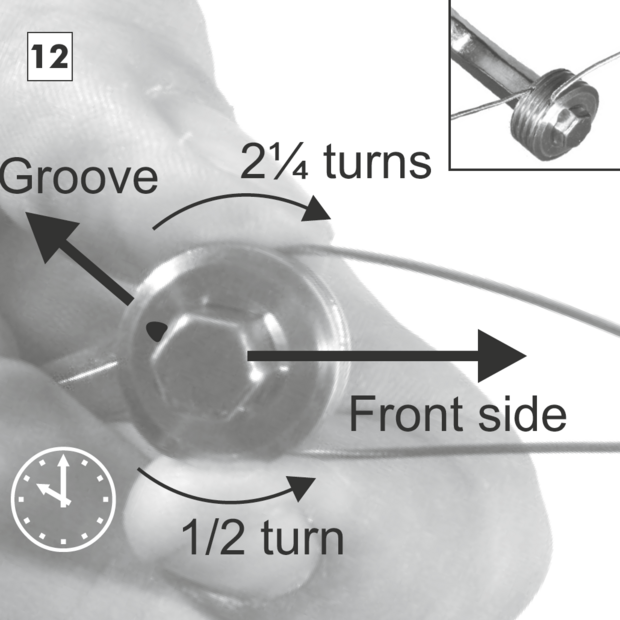

Check the rear side cable is pulled out to its end stop. Measure this cable and cut it at 165mm with sharp wire cutters (see Tip). Place a new concertina tube carefully over the cable and place the male bayonet connector onto the end of the cable.

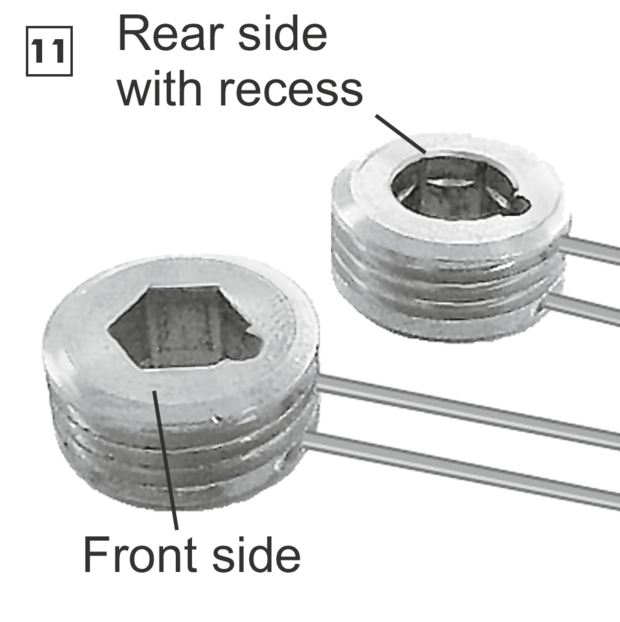

Push the cable up into the male bayonet connector as far as it will go and tighten the two 4mm headless screws with a 2mm allen key (tightening torque 1.5Nm/12”lbs.). Pull the side cable with pliers through the 13 clicks of the gearbox until the end stop (gear #1). Measure* this cable and cut it at 165mm with sharp wire cutters.

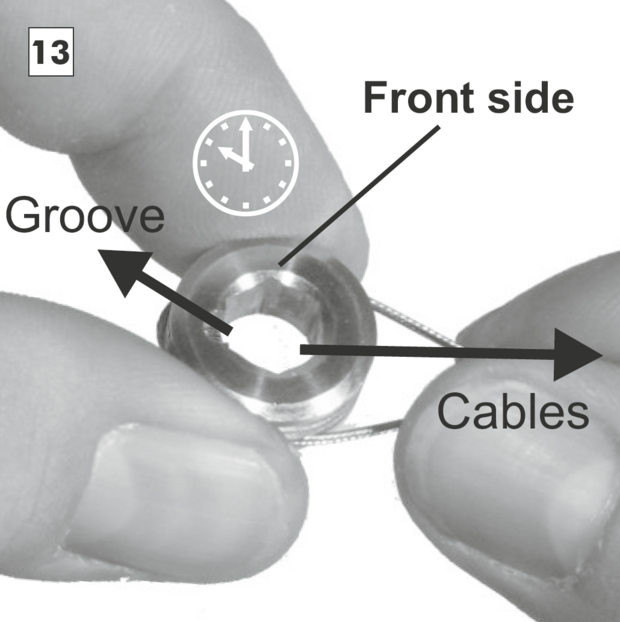

Place a new concertina tube and male bayonet connector over the cable. Tighten up the connector as with the other. Pull the shorter cable until both of the hub cables are approx. the same length. Place the two new concertina tubes over the cable guides and secure them with cable ties. Make sure that the cable ties clamp the concertina tubes over the recess in each of the cable guides.

Tip

* For easier measurement of the correct cable length the special measuring pipe (Art. #8711) can be ordered. Simply place the measuring pipe as far down as possible over the cable. Cut the cable at the end of this pipe, then slide the new concertina tube over the pipe. Remove the measuring pipe, secure the male connector and the concertina tube in the correct positions.