The correct spoke choice

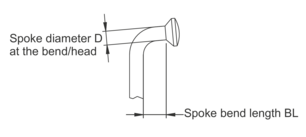

There are a confusing amount of different spokes currently available on the market. These differ not only by their length and diameter, but also more importantly by the differences in the spoke bend at the head. To accomplish the optimal longevity of both the hub flange, the spoke itself and the entire wheel, the spoke bend dimensions must be harmonized with both the hub flange and the spoke holes. It is not sufficient enough to simply choose a spoke according to its length and diameter (eg. 2.0-256mm), the spoke bend itself must additionally be harmonized with the spoke hole so that the spoke can find its optimal sit within the spoke holes of the hub flange.

The correct spoke geometry can be easily identified as follows:

Thread a spoke from outside through the hub flange of the hub cap side so that the spoke head finds its seat within the countersink of the spoke hole. This should be possible without requiring any noticeable force. Hold the hub so that the flanges are horizontal and the sprocket side faces upwards. The spoke should be facing radially outwards. The threaded end of the spoke should now find itself within the shaded area shown on the diagram below. Fig. b.

Repeat this process. This time thread the spoke from the inside, outwards through the spoke flange on the sprocket side of the hub. Again, the spoke head should be seated within the countersink of the spoke hole and this without requiring a noticeable amount of force. Hold the hub so that the flanges are horizontal with the spoke facing radially outwards. The threaded end of the spoke should now find itself within the shaded area shown on the diagram below. Fig. e.

Determing the Rims Internal Diameter

Determing the effective rim diameter (ERD)

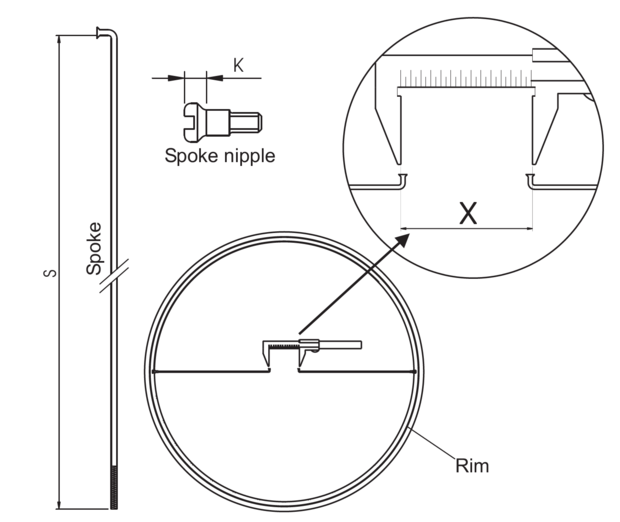

Should the effective rim diameter need to be measured because the rim was not listed in the previous table, the following steps can be used to determine this:

- Measure the head height K of the spoke nipples that ar e intended for use.

- Measure the spoke length S from beginning of the thread to the inside of the 90° bend.

- Thread a spoke through the rim and screw the nipple onto this so that the end of the spoke is level with the head of the spoke nipple.

- Place a second spoke through the spoke hole of the opposing side of the rim and screw the nipple onto this spokein the same way.

- Pull these two spokes together and measure the distance X.

The effective rim diameter can now be determined using the formula: d = 2 x S + X - 2 x K

Spoke Lengths

Spoke lengths for 32/36 hole rims

The Rohloff SPEEDHUB 500/14 uses a spoke hole circle diameter of 100mm with 2.7mm diameter spoke holes (2.5mm up until Serial No.44321). When lacing the Rohloff SPEEDHUB 500/14 into a 26” wheel, the spoke sizes required will usually prove fairly difficult to find in the average bike shop. For this reason silver ‘Sapim Race’ spokes 2.0/1.8/2.0mm with 14mm Secure nipples are available from Rohloff in lengths of 228mm to 244mm. The most commonly used spoke length (for 26" wheels) of 238mm is also available in black. Below is a table showing the required spoke lengths for 32/36 spoke rims. Due to the symmetrical hub flanges of the SPEEDHUB 500/14, the spokes are the same length on both sides of the Wheel:

On wheel sizes 26" and 28" the wheel must always be laced in a two cross pattern. Therefore, the table above shows the spoke lengths for a two cross lacing pattern. On wheel sizes 24" and under, the spokes must only be laced in a one cross lacing pattern. For this reason, the table above shows the spoke lengths for a one cross lacing pattern.

A constantly updated list of spoke lengths can be found on the internet under www.rohloff.de. A spoke length calculator can also be found on our homepage to help work out other correct lengths of spokes that may be required (www.rohloff.de/en/technical/speedhub/spoke_lengths/index.html).

SPEEDHUB O.L.D. - 135mm, 142mm, 148mm

32-hole Hub-shell Spoke lengths

| Wheel Size |

Number of Spoke Crosses | ERD* |

32-hole Spoke lengths |

|---|---|---|---|

| 18" | 1 | 341-343 | 128 |

| 344 | 130 | ||

| 20" | 1 | 372-373 | 142 |

| 374-377 | 144 | ||

| 378-381 | 146 | ||

| 382-385 | 148 | ||

| 386-389 | 150 | ||

| 390-394 | 152 | ||

| 24" | 1 | 472-476 | 192 |

| 477-480 | 194 | ||

| 481-484 | 196 | ||

| 485-489 | 198 | ||

| 490-493 | 200 | ||

| 494-497 | 202 | ||

| 498-501 | 204 | ||

| 502-503 | 206 | ||

| 26" | 2 | 516-519 | 226 |

| 520-523 | 228 | ||

| 524-527 | 230 | ||

| 528-531 | 232 | ||

| 532-535 | 234 | ||

| 536-539 | 236 | ||

| 540-543 | 238 | ||

| 544-547 | 240 | ||

| 548-551 | 242 | ||

| 552-555 | 244 | ||

| 650B | 2X | 556-559 | 246 |

| 560-563 | 248 | ||

| 564-567 | 250 | ||

| 568-571 | 252 | ||

| 572-575 | 254 | ||

| 576-579 | 256 | ||

| 580-583 | 258 | ||

| 28" | 2 | 584-587 | 260 |

| 588-592 | 262 | ||

| 593-596 | 264 | ||

| 597-600 | 266 | ||

| 601-604 | 268 | ||

| 605-608 | 270 | ||

| 29" | 2 | 609-612 | 272 |

| 613-616 | 274 | ||

| 617-620 | 276 | ||

| 621-624 | 278 | ||

| 625-628 | 280 | ||

| 629-632 | 282 |

36-hole Hub-shell Spoke lengths

| Wheel Size |

Number of Spoke Crosses | ERD* |

36-hole Spoke lengths |

|---|---|---|---|

| 18" | 1 | 341-342 | 126 |

| 343-344 | 128 | ||

| 20" | 1 | 372-375 | 142 |

| 376-379 | 144 | ||

| 380-383 | 146 | ||

| 384-387 | 148 | ||

| 388-392 | 150 | ||

| 393-396 | 152 | ||

| 24" | 1 | 472-474 | 190 |

| 475-478 | 192 | ||

| 479-482 | 194 | ||

| 483-486 | 196 | ||

| 487-490 | 198 | ||

| 491-494 | 200 | ||

| 495-498 | 202 | ||

| 499-502 | 204 | ||

| 503 | 206 | ||

| 26" | 2 | 516-517 | 222 |

| 518-522 | 224 | ||

| 523-526 | 226 | ||

| 527-530 | 228 | ||

| 531-534 | 230 | ||

| 535-538 | 232 | ||

| 539-542 | 234 | ||

| 543-546 | 236 | ||

| 547-550 | 238 | ||

| 551-554 | 240 | ||

| 555-558 | 242 | ||

| 559-562 | 244 | ||

| 650B | 2 | 563-566 | 246 |

| 567-570 | 248 | ||

| 571-574 | 250 | ||

| 575-578 | 252 | ||

| 579-582 | 254 | ||

| 28" | 2 | 583-586 | 256 |

| 587-590 | 258 | ||

| 591-594 | 260 | ||

| 595-598 | 262 | ||

| 599-602 | 264 | ||

| 603-607 | 266 | ||

| 29" | 2 | 608-611 | 268 |

| 612-615 | 270 | ||

| 616-619 | 272 | ||

| 620-623 | 274 | ||

| 624-627 | 276 | ||

| 628-631 | 278 |

It is recommended to lace 26", 27.5"/650B, 28” and 29" diameter wheels in a 2 cross pattern - never 3 cross or more. The spoke lengths listed in the tables above always reflect this 2 cross lacing pattern. Wheels smaller than 26" diameter must be laced in a 1 cross pattern and again, the spoke length tables above will reflect this requirement.

SPEEDHUB O.L.D. - 170mm, 177mm, 190mm, 197mm

Spoke lengths for 32-hole XL/XXL (Fatbike) Hub-shells (min. 12.5mm nipple offset requried)

| Wheel Size |

Number of Spoke Chrosses | ERD* |

32-hole Spoke lengths 12,5 mm Offset |

32-hole Spoke lengths 20mm Offset |

|---|---|---|---|---|

| 26" | 2 | 516-519 | 228 | 226 |

| 520-523 | 230 | 228 | ||

| 524-527 | 232 | 230 | ||

| 528-531 | 234 | 232 | ||

| 532-535 | 236 | 234 | ||

| 536-539 | 238 | 236 | ||

| 540-544 | 240 | 238 | ||

| 545-548 | 242 | 240 | ||

| 549-552 | 244 | 242 | ||

| 553-556 | 246 | 244 | ||

| 650B | 2 | 557-560 | 248 | 246 |

| 561-564 | 248-250 | 248 | ||

| 565-568 | 250-252 | 250 | ||

| 569-572 | 252-254 | 252 | ||

| 573-576 | 254-256 | 254 | ||

| 577-580 | 256-258 | 256 | ||

| 581-584 | 258-260 | 258 | ||

| 585-588 | ✘ | ✘ | ||

| 29" | 2 | 589-592 | ✘ | ✘ |

| 593-596 | ✘ | ✘ | ||

| 597-600 | ✘ | ✘ | ||

| 601-604 | ✘ | ✘ | ||

| 605-608 | ✘ | ✘ |

Calculating the spoke length (32 + 36)

The formula below can be used to calculate the correct spoke length should your rim ERD not listed in the table

Spoke length: L=square root of ( 0.25 x d² ) + 3400 - (50 x d x c)

d: effective rim diameter in mm

c = 0.924 with 1 cross pattern (32 hole)

c = 0.707 with 2 cross pattern (32 hole)

c = 0.940 with 1 cross pattern (36 hole)

c = 0.770 with 2 cross pattern (36 hole)